How Epoxy Busbar Support Insulators Enhance the Functionality of Distribution Boxes

When it comes to modern electrical systems, distribution boxes, and epoxy busbar support insulators work together like a team. Whether you’re powering a small facility or a massive industrial setup, these components are essential to keep things running smoothly and safely. Let’s dive into why epoxy busbar support insulators are a game changer and how they enhance the functionality of distribution boxes.

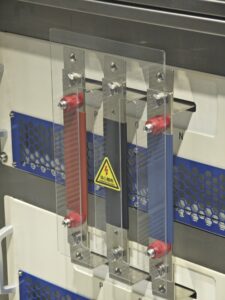

1. Why Distribution Boxes Need Epoxy Insulators

Imagine your distribution box as the heart of your electrical system, carrying power to where it’s needed. Now, think of epoxy busbar support insulators as the arteries that keep everything steady and safe. Without them, you’re looking at potential chaos.

Here’s why they’re essential:

Electrical Isolation: Epoxy busbar support insulators separate live electrical components, reducing the risk of short circuits and improving overall system reliability.

Load Bearing: These epoxy busbar support insulators are designed to support the weight and stress of the busbars inside the distribution box.

Heat Resistance: Epoxy’s high thermal stability ensures the system can handle heat generated during operation without any risk of damage.

Durability: Resistant to moisture, corrosion, and chemicals, epoxy busbar support insulators are built to last even in harsh environments.

Without epoxy busbar support insulators, distribution boxes would struggle to maintain safety, efficiency, and reliability.

2.The Key Role of Epoxy Insulators in Distribution Boxes

Epoxy busbar support insulators aren’t just optional extras; they’re a vital part of any well-designed distribution box. Here’s a closer look at their key roles:

2.1 Providing Structural Stability

They anchor and support the busbars, preventing them from shifting or sagging over time.

This keeps the internal wiring organized, which is crucial for maintenance and safety checks.

2.2 Improved Electrical Safety

Epoxy busbar support insulators provide a protective barrier, ensuring live components don’t come into contact with each other or with the box itself.

This minimizes the risk of arcing, short circuits, and electrical fires.

2.3 Reducing Maintenance Needs

With their robust build, epoxy insulators reduce wear and tear on the system, cutting down on maintenance costs.

Busbar support insulators’ resistance to moisture and chemicals makes them ideal for environments where exposure to these elements is a concern.

In short, they’re the unsung heroes of your electrical system, working behind the scenes to ensure everything runs smoothly.

3.Boosting Distribution Box Performance with Epoxy Insulators

Epoxy busbar support insulators don’t just maintain the functionality of distribution boxes; they take it to the next level. Let’s explore how:

3.1 Improved Efficiency

By holding busbars securely in place, busbar support insulators reduce energy losses caused by vibration or poor connections.

The heat-resistant properties of busbar support insulators mean that they can handle high loads without degrading performance.

3.2 Component longevity

The insulating properties protect busbars and other internal components from damage, extending their lifespan.

This results in fewer system downtimes and replacements.

3.3 Versatility Across Applications

Whether it’s a residential installation, a commercial project, or an industrial system, epoxy insulators adapt to various requirements.

Example

Consider a manufacturing plant that relies on multiple distribution boxes. Without epoxy insulators, vibrations, and heat would cause connections to weaken over time, leading to costly downtime. With epoxy insulators, the system remains robust and reliable, ensuring uninterrupted operation.

4.How Epoxy Insulators Improve Distribution Systems

When we zoom out and look at the bigger picture, it’s clear how epoxy insulators improve the overall distribution system.

Key Improvements:

Better Load Distribution: By stabilizing busbars, epoxy busbar support insulators ensure the even distribution of electrical loads.

Higher Safety Standards: Epoxy Support Insulators meet stringent safety regulations, making them a reliable choice for modern systems.

Simplified Design: The strength of epoxy allows for more compact and efficient designs in distribution boards.

In industries like healthcare, where uninterrupted power is critical, epoxy insulators play a vital role in ensuring system dependability.

5.Making Distribution Boxes Safer with Epoxy Insulators

Safety is paramount in any electrical installation, and epoxy busbar support insulators are at the forefront of achieving it. Here’s how they keep systems safe:

5.1 Preventing Electrical Failures

By isolating live components, busbar support insulators prevent accidental contact and potential failures.

5.2 Withstanding Harsh Environments

In environments with high humidity or exposure to chemicals, the robust design of epoxy busbar support insulators ensures continued safety.

5.3 Reducing Human Error

Their clear separation of components reduces the risk of errors during installation and maintenance.

Example:

Think about a power distribution system in a coastal area where humidity and salt are constant challenges. Epoxy busbar support insulators protect against corrosion, ensuring the system remains safe and operational.

FAQs

Q: What are epoxy busbar support insulators made of?

A: They are typically made of high-quality epoxy resin, known for its strength, durability, and excellent insulating properties.

Q: Can I retrofit epoxy insulators into an existing distribution box?

A: Yes, epoxy insulators are versatile and can often be added to existing systems to improve safety and performance.

Q: Are epoxy insulators suitable for outdoor use?

A: Absolutely. Their resistance to moisture, UV rays, and temperature variations makes them ideal for outdoor applications.

Q: How do epoxy insulators compare to traditional materials?

A: Epoxy insulators offer superior durability, better thermal resistance, and improved electrical isolation compared to older materials like porcelain.

Conclusion

Epoxy busbar support insulators are a critical component in modern switchboards, enhancing their functionality, safety and performance. They ensure that your electrical system remains reliable, efficient and safe, whatever the application. By investing in high quality epoxy insulators, you’re not only protecting your equipment, you’re providing peace of mind.

If you’re looking to optimise your power distribution systems, start by upgrading your junction boxes with epoxy busbar support insulators. Trust me, it’s a small change that makes a big difference.

--- END ---

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. All rights reserved.SUPPORT BY:JUNJ Privacy Policy

E-mail:

E-mail:  No. 20 Lingyun Road, Dongfeng

No. 20 Lingyun Road, Dongfeng