Benefits of Busbar Support in SLVA Cabinet

What is an SLVA Cabinet?

SLVA cabinets, in other words, SLVA standardized low-voltage switchgear, are principal parts in electric distribution networks. These cabinets are built to accommodate low-voltage switchgear which is of utmost importance for the management of electrical power in a safe and effective manner. SLVA cabinets are broadly applied in a wide range of industries, from manufacturing to commercial buildings and utilities, to guarantee the reliable functioning of electrical systems.

Why Are Busbar Supports Important in SLVA Cabinets?

SLVA Cabinets house electrical components for power distribution in industrial and commercial settings. As conductive elements inside, busbars need secure positioning and insulation to avoid electrical faults. Given the precise power distribution required by SLVA cabinets, busbar supports are crucial. This is where busbar supports become indispensable.

Structure and Design Features of SLVA Cabinets

SLVA cabinets are made in such a way that they are strong and long-lasting and can protect the low-voltage switchgear. Their design is built around the several features that can be called imperative to the safety, efficiency, and easy maintenance of the equipment. Important design components of SLVA cabinets include::

- SLVA cabinets are usually modular, making it possible to easily expand and customize them according to the user’s needs. The use of modularity makes it possible to add new components or to reconfigure the existing ones as needed.

- SLVA cabinets having a compact design, thus, attain space efficiency which is why they can be installed in several environments such as crowded places. They have space-saver designs that make them appropriate for all kinds of installations, from busy places to structures that have limited space.

- The electrical appliances in the cabinet are secured with cooling and ventilation to take care of overheating. In this way, the equipment gets a long time and suffers no function failures.

- SLVA cabinets are endowed with safety provisions such as arc flash protection, as well as grounding systems and isolation barriers to protect both the equipment and the personnel.

- SLVA cabinet is designed in such a way that all the components can be accessed easily for maintenance and if there is any problem to troubleshoot, thereby reducing the downtime and ensure the efficient operation.

Key Benefits of Using Busbar Supports

To fully understand how busbar supports enhance SLVA cabinet performance, let’s explore their key benefits. Here are six key benefits of using high-quality busbar supports in SLVA Cabinets:

1. Prevents Electrical Short Circuits & Arcing

Poorly secured busbars increase the risk of short circuits, which can lead to system failure, electrical fires, or catastrophic damage. Busbar supports keep conductors properly spaced and insulated, preventing accidental contact and ensuring safe operation.

2. Enhances Structural Stability & Vibration Resistance

SLVA Cabinets often operate in environments with mechanical vibrations, such as industrial plants and commercial buildings. Busbar supports reinforce the structure, preventing unwanted movement that could cause wear and eventual failure.

3. Improves Heat Dissipation & Prevents Overheating

Busbars conduct high currents, generating heat. If not properly supported, heat buildup can accelerate material degradation, reducing efficiency. Well-designed busbar supports enhance airflow, helping dissipate heat and prolong the system’s lifespan.

4. Increases Electrical Safety for Operators & Equipment

Unsecured busbars pose an electrocution hazard for maintenance personnel and increase the likelihood of system-wide failures. Proper busbar insulation and support minimize the risk of electrical shocks and arc flashes, ensuring compliance with safety regulations.

5. Reduces Maintenance Costs & Extends Equipment Lifespan

A stable busbar system reduces mechanical wear, thermal expansion issues, and electrical degradation, resulting in lower maintenance needs and longer service life for SLVA Cabinets. This translates to reduced downtime and operational costs.

6. Supports Compliance with Electrical Safety Standards

High-quality busbar supports are manufactured to meet international electrical safety standards (IEC, UL, and other industry certifications). Using certified supports ensures your SLVA Cabinet complies with safety and performance regulations.

Materials and Selection Standards for Busbar Supports

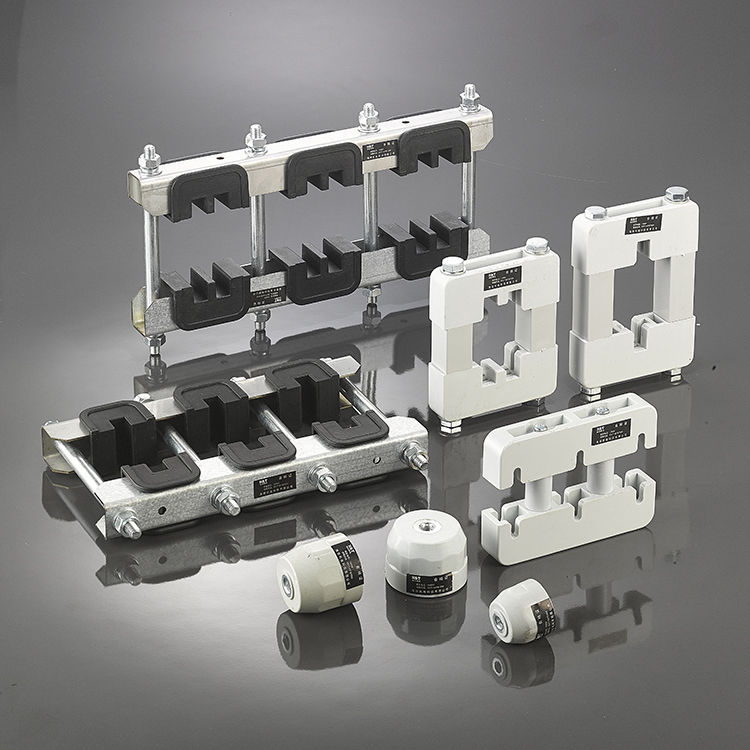

Busbar supports are key components within SLVA cabinets, providing mechanical stability and electrical insulation for busbars. The selection of materials for busbar supports is crucial to ensure their performance and longevity. Common materials used for busbar supports include:

Materials

- Epoxy busbar supports have excellent electrical insulation capabilities, mechanical strength, and resistance to environmental factors such as humidity and temperature changes.

- Another popular busbar support material is a glass-reinforced plastic (GRP), which has higher strength-to-weight ratio, electrical insulation, and corrosion resistance.

- Ceramic busbar supports have high electrical insulation and heat resistance for applications with extreme temperature changes.

Selection Standards

- IEC 61439: It consists of the essential criteria for the low voltage switchgear and control gear assemblies with details of the materials and the design of bus route supports.

- UL 94: A standard on the flammability of plastic materials, thus, the protection of busbar supports as per the fire safety standards.

- ASTM D638: A standard test method for the evaluation of the plastic tensile properties represents the mechanical power of busbar support material.

How To Install Busbar Support In Low Voltage Switchgear?

The installation of busbar supports in SLVA cabinets is a critical process that requires careful planning and execution. The steps involved in the installation process include:

- Planning and Layout: The busbars and supports are laid out in a way that they can be spaced and aligned to get the best performance. In this case, it is necessary to consider facts like the current capacity, expansion heat, and mechanical stability.

- Mounting the Supports: Busbar supports are mounted inside the SLVA cabinet with proper fasteners and brackets. The correct placement is important to prevent the mechanical stresses from being unevenly distributed.

- Precise Busbars Positioning: Supports are used to put busbars on the supports, making sure they are fastened and aligned. Special attention is given to the fact that no sharp bends and stress points are encountered which may cause mechanical failure.

- Electrical Connections: Busbar and switchgear components are making electrical connections in the busbars and switchgear components. This refers to the compliance with proper torque settings and using the correct connectors to maintain electrical integrity.

- Testing and Inspection: After the installation, a very careful testing and inspection are conducted to verify electric and mechanical integrity of the busbar supports and connections. Conducting testing for insulation resistance, continuity and mechanical stability are also included.

Click To View More Busbar Support Products>>

Case Studies: Application of Busbar Supports in SLVA Cabinets

Case Study 1: Industrial Manufacturing Plant

An industrial manufacturing plant regularly faced electrical malfunctions and operational stoppages due to defective busbar supports in their SLVA cabinets. After the transformation of epoxy busbar insulators, the factory witnessed a steep drop in disruptions, mainly thanks to the considerable improvement in the plant’s reliability as a whole. The extraordinary ability of the supports to operate under heavy current loading was ensured as the material’s higher thermal resistance and mechanical strength provided more stability.

Case Study 2: Commercial Building

A commercial building with a complicated electrical distributing system needed a dependable solution to avoid electricity malfunctions and always provide a constant power supply. The installation of busbars with glass-reinforced polyester (GRP) in their SLVA cabinets not only provided the required electrical insulation but also improved the mechanical stability of the system. The building’s electrical control and maintenance department has noticed a decrease in the number of electrical faults and also improvement in the safety of the maintenance personnel.

Case Study 3: Utility Substation

A utility substation was in need of the SLVA cabinets upgrade to accommodate higher current capacities and ensure the distribution of power remained reliable. The ceramic busbar supports were able to fulfill both the desired thermal and electrical insulation properties. Most notable, the application of this technology led to heightened performance and reliability for the substation. The new supports handled the thermal stresses and mechanical loads excellently.

We all know the significance of busbar supports within the SLVA cabinets, which are very essential for the proper and safe functioning of the whole range of electrical current distribution systems. These components are made up of the materials that are fitted and installed correctly such as the busbar supports that contribute to the overall performance, safety, and longevity of the switchgear components housed within SLVA cabinets.

--- END ---

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. All rights reserved.SUPPORT BY:JUNJ Privacy Policy

E-mail:

E-mail:  No. 20 Lingyun Road, Dongfeng

No. 20 Lingyun Road, Dongfeng