Busbar Insulator Maintain and Manage

Busbar insulators are important components in power systems and electrical equipment. They protect and insulate the busbar and other metal components. They can also provide necessary mechanical support to protect the safety and stability of busbar operation. Therefore, daily maintenance and management of busbar insulators are very necessary. This blog will introduce in detail how to maintain and manage busbar insulators to help your busbar insulators operate stably for a long time.

1.Busbar Insulators Regular Inspection

Regular inspection is very necessary. Through inspection, problems can be found and dealt with in time. In this step, we can use routine visual inspection to see whether the overall appearance of the insulator is good and whether the position of the insulator and the busbar is correct. If the appearance of the busbar insulator is found to be cracked, deformed or aged during the inspection, we should replace it in time to ensure that it can provide good insulation and support for the busbar. At the same time, the loose connection between the busbar and the insulator can be reinforced to ensure that the busbar insulator can have good contact with the busbar and provide efficient insulation.

2.Busbar Insulators Testing electrical performance

The most important function of busbar insulators is to provide insulation protection between busbars and other metal components. Therefore, in daily maintenance, we must regularly detect the electrical performance of busbar insulators to ensure that their insulation resistance values meet the corresponding national standards. For example, according to the IEC standard, in low-voltage busbars, we use a 500V Megger to test the insulation resistance value of busbar insulators. Generally, the insulation resistance value must be 100

MΩ to meet the standard. In high-voltage busbars, 2500V and above Megger are generally used to test the insulation resistance value. Generally, the insulation resistance value must not be less than 1000 MΩ. According to this standard, we detect the electrical performance of busbar insulators. If there are insulators below this standard, it may mean that the insulator has aged or damaged, and it is necessary to consider repairing or replacing the insulator. Especially in high temperature, high pressure or harsh environments, the detection of electrical performance is particularly important to ensure the stable operation of the entire system.

3.Busbar Insulators Connection inspection

The stability of the busbar insulator can ensure good insulation between the busbar and other electrical components and guarantee the operation of the system. Therefore, we should regularly check the fixation of the busbar insulator and the connection with the busbar, and check whether the busbar insulator and the bracket are loose, moved or corroded. If any problems are found, they need to be dealt with in time, reinforced or cleaned to ensure that the busbar insulator can perform at its best performance.

4.Busbar Insulators Anti-corrosion protection

The anti-corrosion protection of busbar insulators is very important, especially in high temperature, high pressure or harsh environments. Busbar insulators may be easily corroded by the environment over time, thus affecting their insulation performance. Therefore, it is necessary to regularly inspect and protect the busbar insulators for corrosion. This is the key factor to ensure that it can stably exert its insulation performance. Therefore, if dirt or dust is found on the surface of the insulator during inspection, it needs to be cleaned up in time. For those that have part of the surface peeling off or the anti-corrosion layer is damaged, the anti-corrosion layer should be re-applied in time or a new busbar insulator should be replaced.

5.Busbar Insulators Temperature monitoring

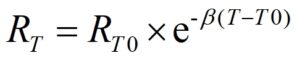

According to the following mathematical formula for the relationship between temperature and resistance, which is widely used in physical science and material science, (R_T0 taking 100MΩ, e is the base of the natural logarithm), we calculated the changes of busbar insulators with temperature:

| Temperature coefficient of insulating material(β) | Temperature(℃) | R_T Resistance Value(MΩ) |

| 0.04 | 20 | 100 |

| 25 | 81.8 | |

| 30 | 67.0 | |

| 35 | 54.8 | |

| 40 | 44.9 |

It can be seen that the insulation performance of busbar insulators will decrease with the increase of temperature. When the temperature increases by 10℃, the insulation resistance value decreases by 32.9%. When the temperature increases by 20℃, the insulation resistance value decreases by 55.1%. Therefore, we must regularly use infrared thermometers or other thermometers to monitor the temperature of busbar insulators, especially in high current load systems, to avoid overheating of insulators, causing aging of insulators and reducing their insulation performance. If the temperature of busbar insulators is found to be too high, emergency measures such as reducing their load, checking whether their contact points are good, and improving cooling can be taken to ensure the safety and stability of the system.

6.Busbar Insulators Cleaning and replacement

Keeping the surface of the busbar insulator clean can extend its service life and stabilize its performance. As time goes by, the busbar insulator will be contaminated by dust, salt or other pollutants in the environment, so it is necessary to clean the busbar insulator regularly. You can use a clean rag or a small brush with a professional detergent to clean it. Avoid using corrosive detergents or detergents that can damage the surface coating of the insulator. For insulators that cannot be cleaned and affect the insulation performance, we need to replace them, so that the busbar insulator can perform at its best and protect the safety of the busbar and other electrical components.

7. Documentation

Archiving each maintenance record is crucial for long-term operation management, providing necessary records and data support, and providing practical knowledge for subsequent training and education. Therefore, it is necessary to ensure that after each maintenance, the maintenance parts, problems found, rectification measures, and responsible persons are recorded in detail according to the corresponding standards.

8. Training and education

The maintenance and management of busbar insulators requires continuous learning of new knowledge, understanding of the latest maintenance knowledge and specific operating skills, and mastering the necessary emergency response methods. Therefore, it is necessary to regularly train and educate relevant personnel to ensure that they have a proficient understanding of the correct use of operating tools and the overall structure and connection method of busbar insulators.

Conclusion

Busbar insulators are key components that provide electrical insulation and mechanical support for busbars. They play an important role in electrical systems. In order to ensure their performance and service life, it is very necessary to learn how to maintain and manage bus insulators. Through the maintenance methods and maintenance theory knowledge introduced in this article, you can improve the stability of your bus insulators and improve the knowledge reserve of your bus insulator maintenance workers.

FAQS

Q: What is a busbar insulator?

A: A busbar insulator is an insulating device used to support and fix the busbar, which plays the role of electrical isolation and preventing line short circuit.

Q: How often should busbar insulators be maintained?

A: Generally, we recommend inspection and maintenance every three to six months. If the environment is particularly harsh, the inspection frequency should be increased to ensure the stable performance of the busbar insulator.

Q: What are the materials of busbar insulators?

A: The materials of busbar insulators are generally ceramic, glass, epoxy resin, polymer (composite material), etc.

--- END ---

© Copyright 2024 China Haitan Electromechanical Technology Co., Ltd. All rights reserved.SUPPORT BY:JUNJ Privacy Policy

E-mail:

E-mail:  No. 20 Lingyun Road, Dongfeng

No. 20 Lingyun Road, Dongfeng